During the research and development of KDR series rotary scroll oil free air compressor technology, it attach much importance to reducing unnecessary maintenance cost and time and supplying 100% oil free compressed air. Rotary scroll oil free innovation technology avoids the trouble of adding lubricating oil and the risk of existence of oil in rear part of the system. What’s more, continuous operation for 24 hours, compact structure and small footprint Provide users with green air source which is oil-free, odourless, clean and dry, no need to add any lubricating oil, so it is environmental friendly, not only compressed air free from oil contamination to end products, but also provide dentist and dental technicians with reliable high quality compressed air Maintenance free, fully automation and easy operation.

FEATURES

The world-class brand as Siemens electronic components products are selected such as relays, contactors and so on. To meet the customer's gas using need, high-performance PLC controller according to controls (automatic start and stop) the loading gas-end number to achieve the entire system operating with low energy consumption; The powerful breakdown diagnosis as well as the protection function, to keep the air compressor operating in more reliable and stable situation. To ensure that we can bring customers with high-quality, safe and durable air compressor control solution program.

Inlet pre-filter design, a large area of the inlet filter core, effective dust filtering, reduce noise, while greatly reducing the inlet pressure resistance, filtration efficiency of up to 99.9%; providing independent access to compressor air-end’s inlet, intake cool Air for improving the compression efficiency.

Using the international advanced oil-free scroll technology, low-speed design to ensure that the scroll head reliability and service life; High-precision moving scroll, static scroll and shell processing, to ensure the high efficiency of the head; compression chamber and lubrication of the transmission. Part of the absolute separation, to ensure absolute oil-free compressed air.

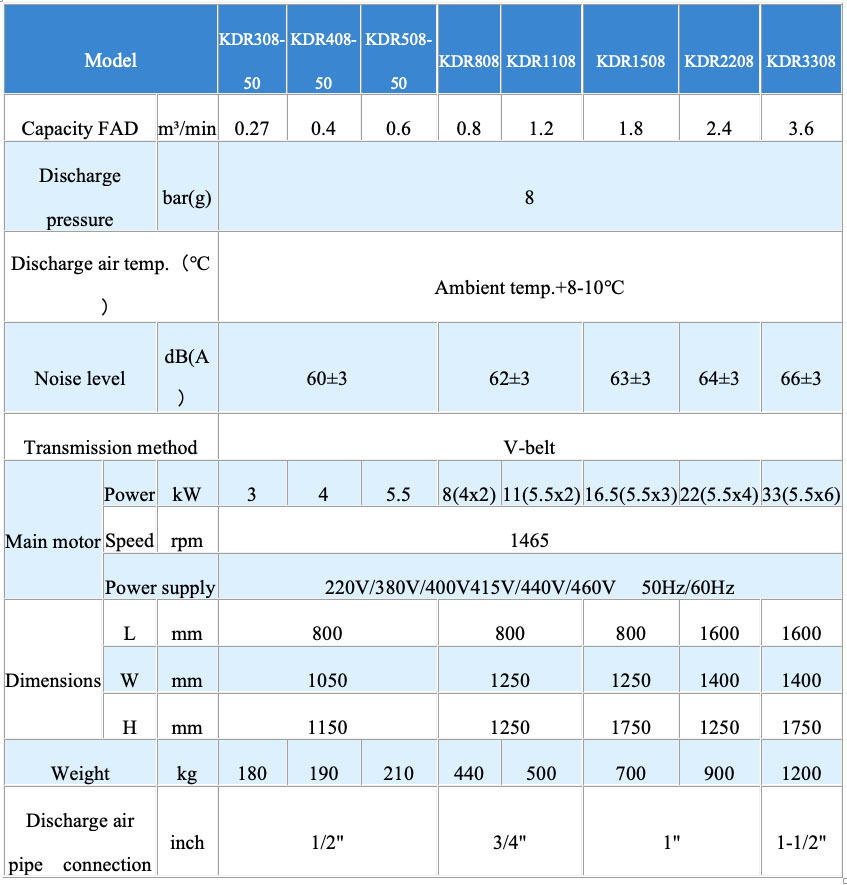

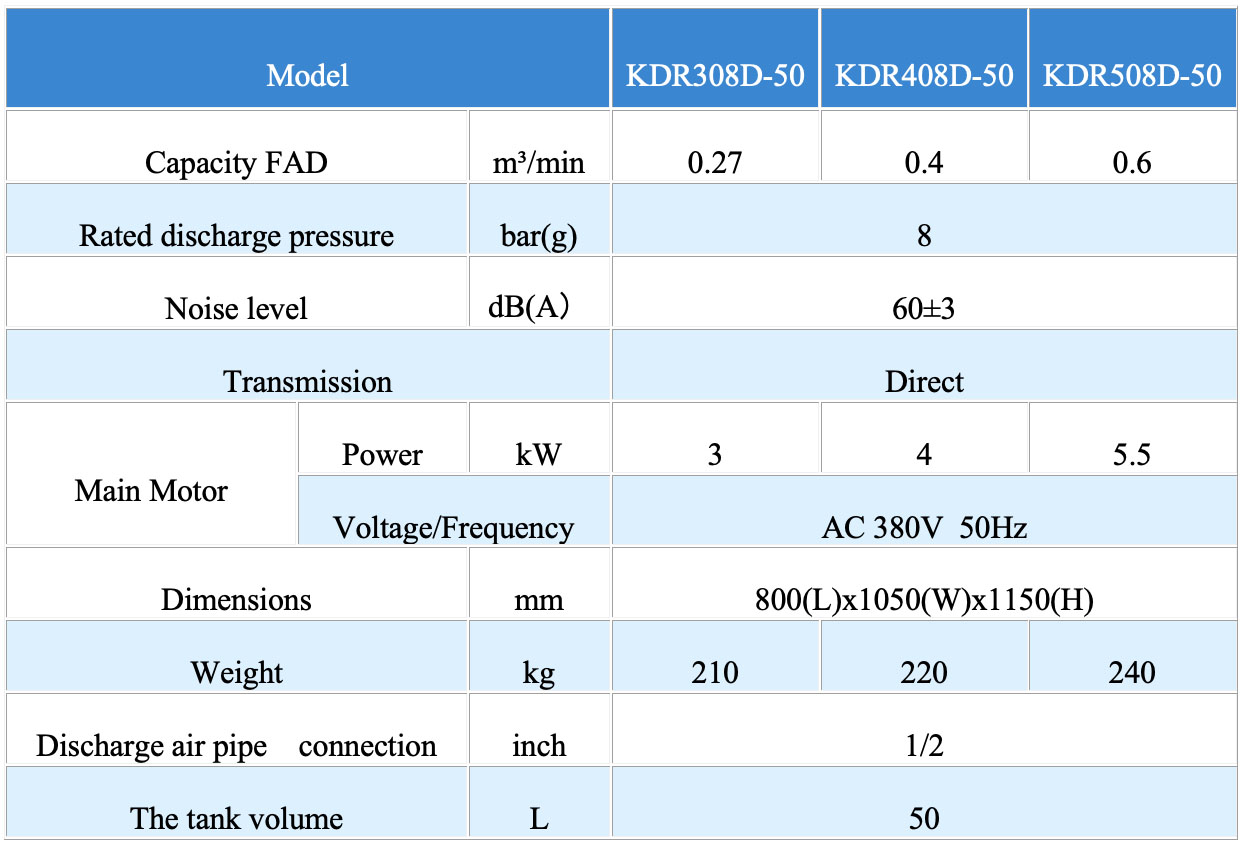

With increased area heat transfer design, and multi-unit models each machine is equipped with one stage and two stage high-efficiency cooler to ensure that the environment in high temperature and humidity, the whole outlet temperature is not higher than the ambient temperature of 8-10 degrees, reduce the load of the user after processing equipment.

Machine shells are multi-sound insulation design, and the inside the surface affixed to high-quality sound-absorbing material, to maximize reduce the noise level.

REMARKS

- Unit performance measured according to ISO 1217, Ed.3, Annex C-1996.

- The noise value refers to the measured value at the time of the full load operation in non-sound chamber (positive 1.5m, high 1m) .

- If all the technical data subject to change, there is no notice; if in doubt, please refer to the manufacturers or dealers to check.