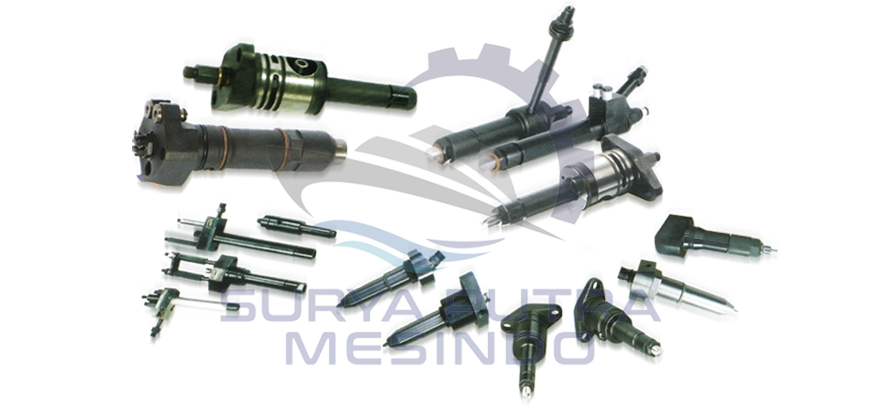

Valve manufacturing starts with forging, and this is where our special skills combines art and technology to create the critical metallurgical structure. Throughout the manufacturing process, our multi-disciplined and experienced teams use the latest production techniques in CAD, CNC machining. Specialist friction and plasma welding, swaging, and conventional machining to ensure integrity of specification and uniformity of finish. To suit individual operating conditions, we incorporate a full range of surface finishes including hard chrome plating, nit riding and molybdenum coating of stems and ‘satellite’ hard facing of seats. From forging to finishing, all processes are kept under stringent control. We supply OEM and Replacement from Japan, German and Korea.