FEATURES

All high quality and durable spare parts are designed, manufactured and tested in Europe to meet with the most stringent international standards.

Optimal energy efficiency and outstanding reliability is achieved from patented design third generation non-symmetric robust rotors, superior bearings and oil seal that help the compressor airend to operate with good dynamic balance, low vibration, low rotation speed and low noise level.

The control and regulation system elaborates the pressure signals received by the sensor included inside converting them into signals that modify the free air capacity.

With a correct programming it is assured a stable flow of compressed air to match the variable demand with a minimum pressure variation.

- To keep under control of all parameters included in the unit -

- To modify the programmed conditions as required (within the preset limits) -

- To determine maintenance requirements -

- To program the stop and start of unit in accordance to the requirements -

- To modify the programmed conditions as required (within the preset limits) -

- To determine maintenance requirements -

- To program the stop and start of unit in accordance to the requirements -

Modern concept suction control valve with automatic closure can prevent any oil escape. The control unit can automatically adjust from 60-100% according to the system air demand to effectively minimize operation cost.

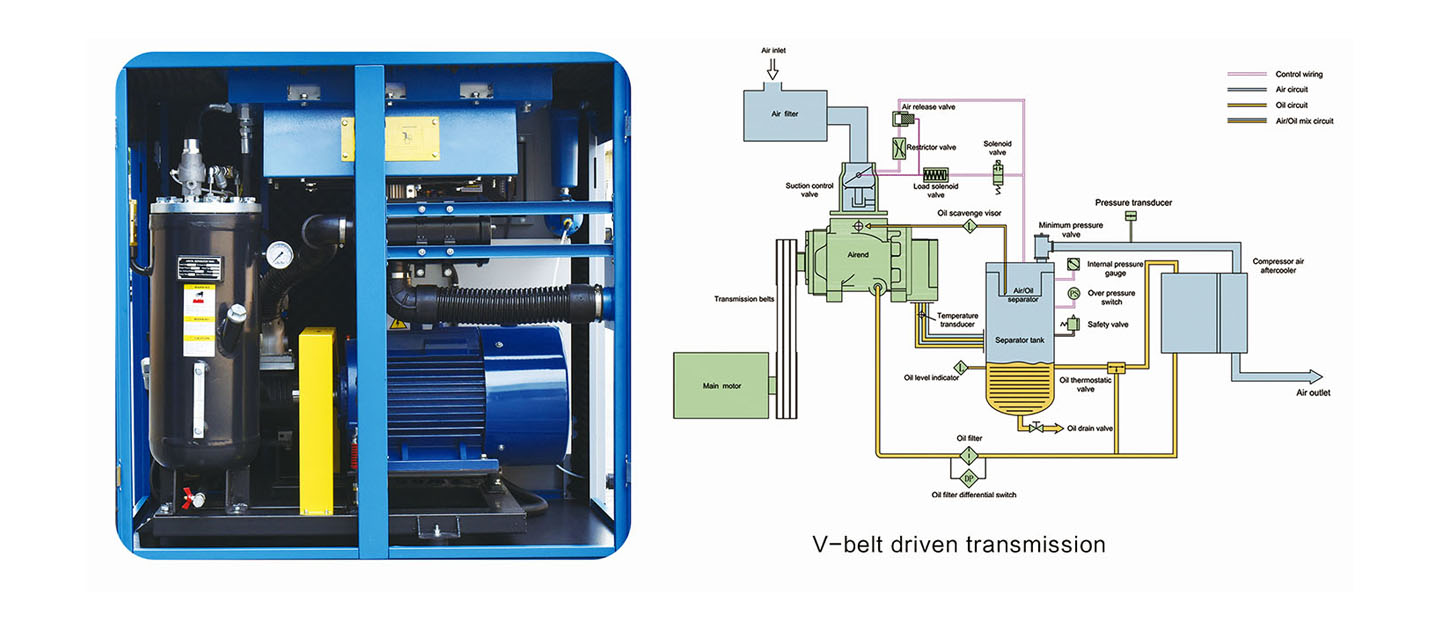

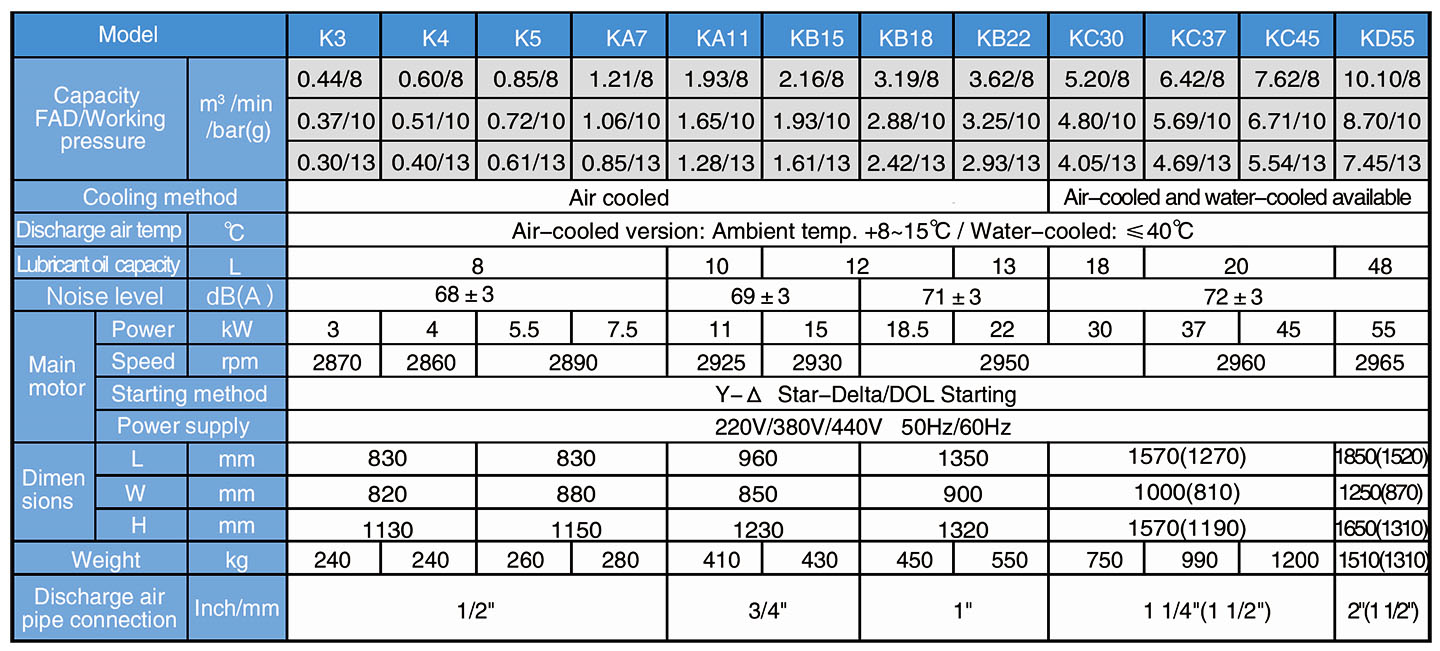

Small to Medium Capacity Models (KA – KD Series)

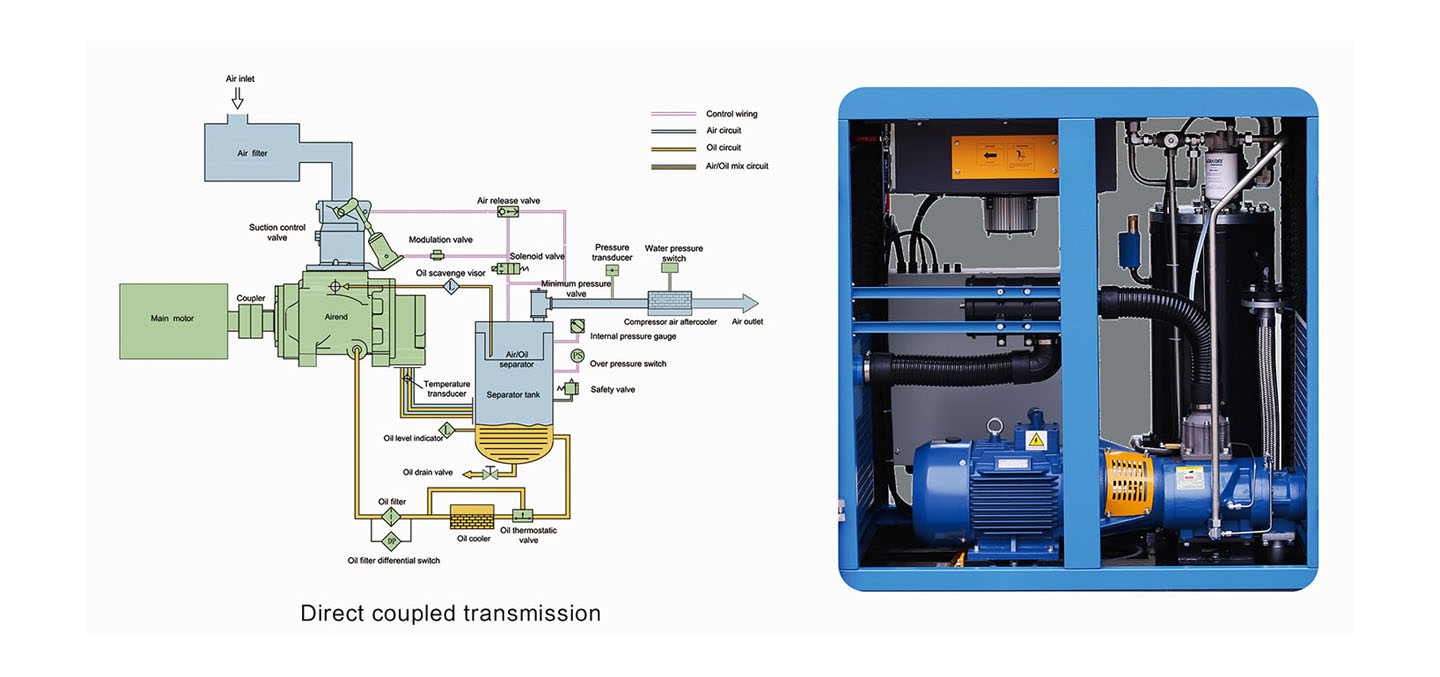

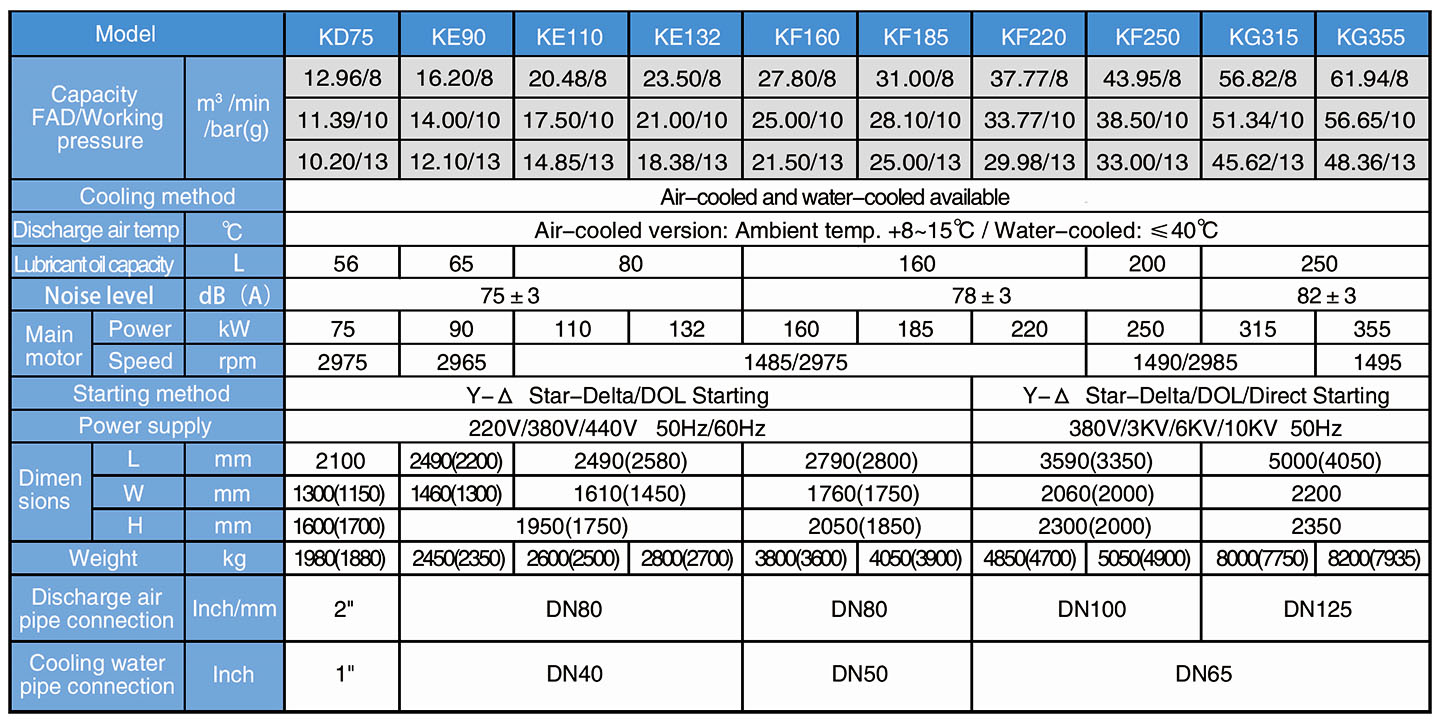

Big Capacity Models (KD – KG Series)

NOTES

- Measured and tested in accordance with ISO1217, 3rd Edition, Annex C (1996).

- Noise level measured in accordance with Pneurop/Cagi PN8NTC test code, error 3dB(A).

- Cooling system specifications are given in brackets.

- If you are ordering 3-5 bar low pressure screw air compressor, please contact local dealer for specifications.

- Any model can be modified with slow starter.

- Adekom may make improvements and/or changes in the appearance and/or specifications without notice.