Have Any Questions !

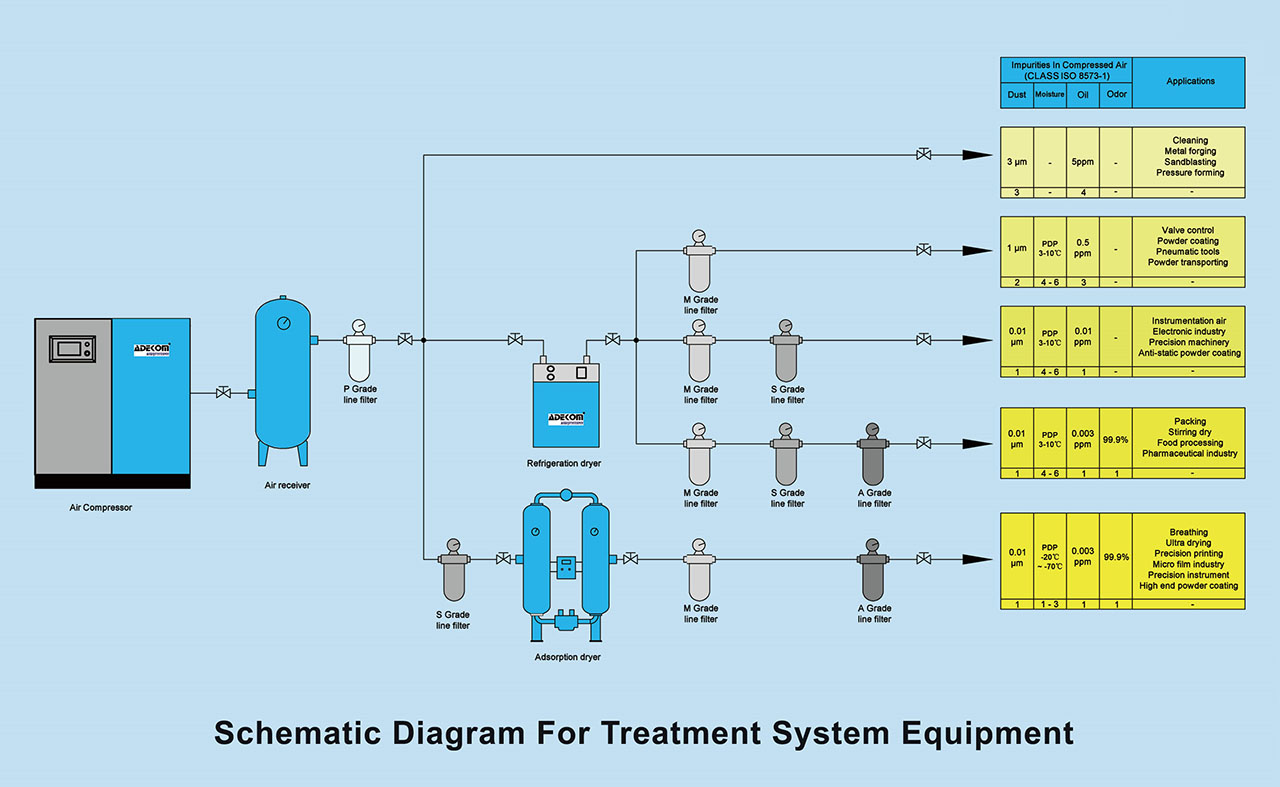

A dry compressed air system is essential to maintain the reliability of production processes and the quality of end products. Untreated air can cause corrosion in pipework, premature failure of pneumatic equipment, and product spoilage. Adekom offers a full range of air and gas dryers, filters, and generators that will protect your systems and processes.

A well designed compressed air system ensures that the air quality demands of the process are closely met. With the desired ISO class as a guide, the appropriate components can be selected.

Over the years, Adekom has innovatively developed and improved air/gas compression and drying techniques. Whatever your application or quality requirements, Adekom can offer the right air/gas treatment solution. Every product is designed, built and individually tested, ISO 9001 and ISO 14001 certified

Intake air from the compressor always contains moisture. With the compression and subsequent cooling, the compressed air is always saturated to 100% with moisture. Anyone who sends compressed air through a pipe network needs to protect against corrosion in order to prevent machine failures or production waste. As a result, each compressed air system includes at least one dryer and/or other processing components, such as filters or condensate separators. Different drying technologies are available: refrigerant dryers for simple applications and desiccant dryers for high to extremely high standards.

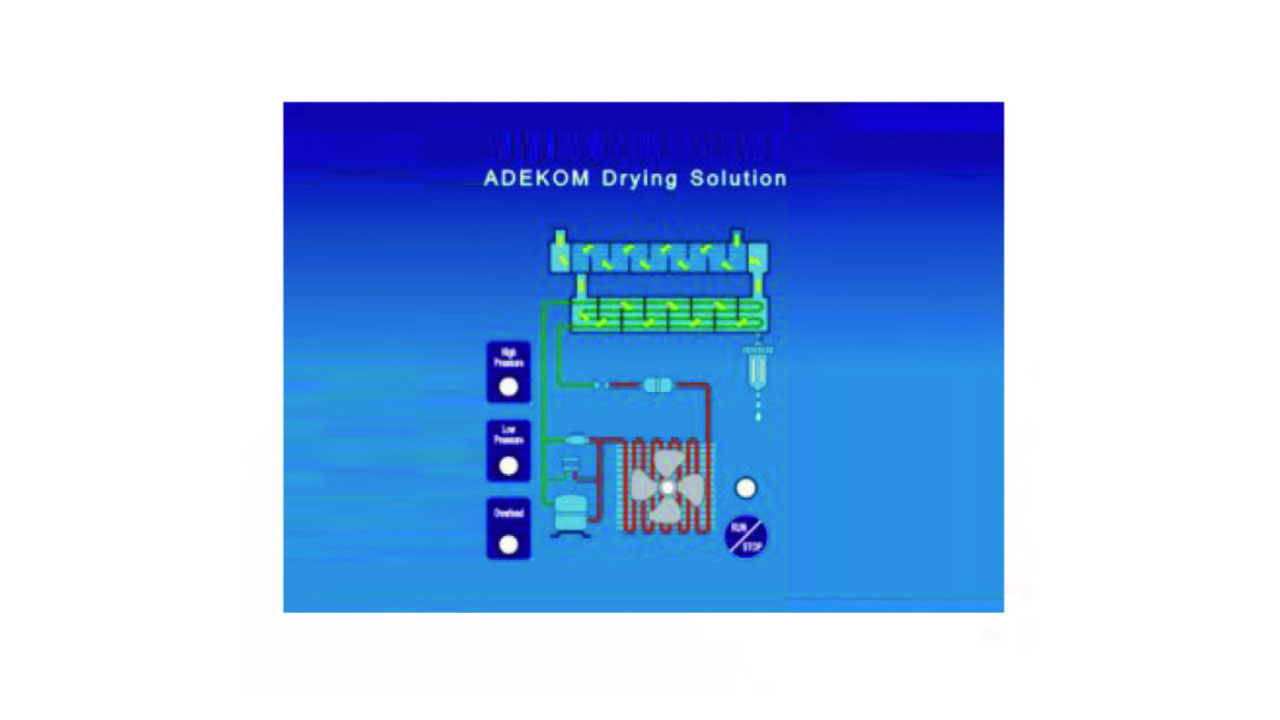

Refrigerant dryers are very reliable and economical. They work with built-in refrigerant compressors, which cool the air via heat exchangers, separate the resulting condensate and produce dry air with a pressure dewpoint of 3°C, so your systems are reliably protected from corrosion.

Dry, quality air is vital for long-term, troublefree operation of your processes. Adekom’s KAD+ dryers protect your products and systems against damage or corrosion.They remove moisture from compressed air with a dew point as low as 3°C/37,4°F. Easy to install, simple to operate and reliable, they provide the dry air you need, allowing you to concentrate on your core business,

KAD + SERIES REFRIGERATED AIR DRYER

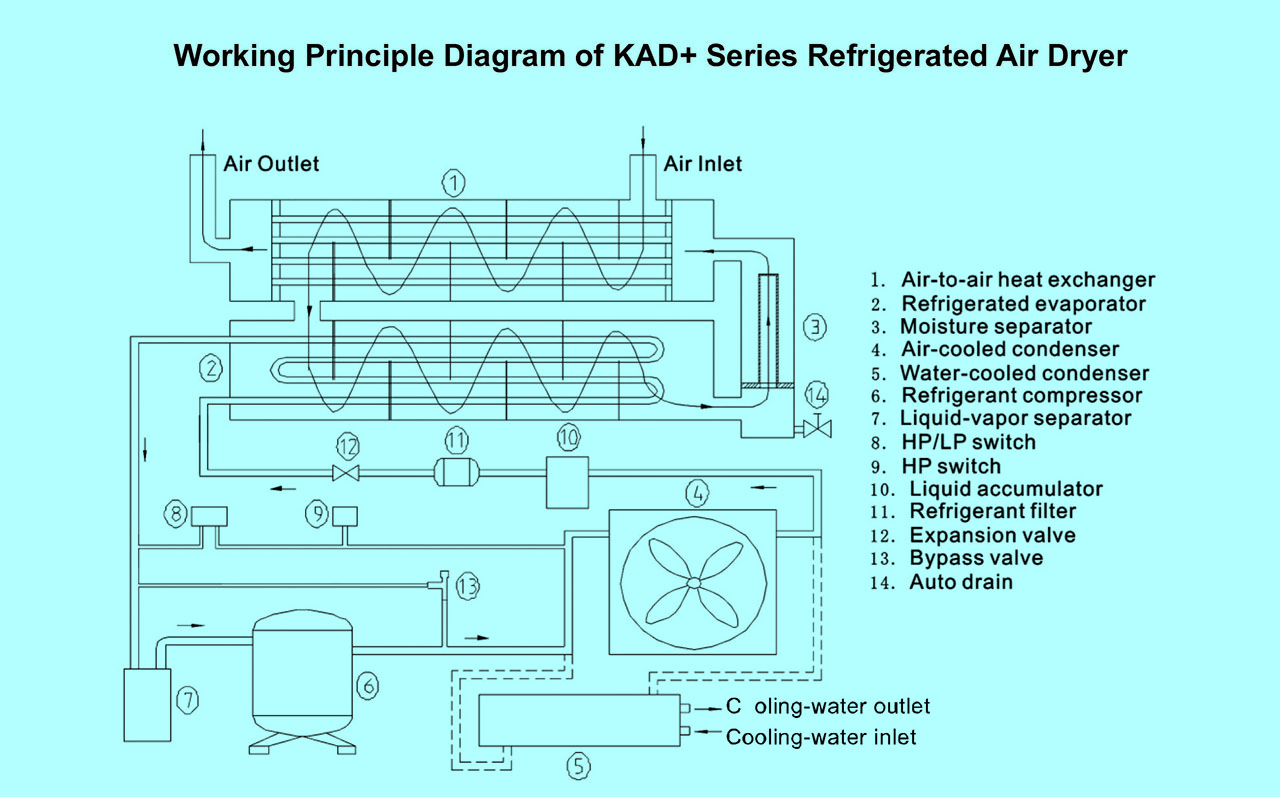

[ AIR CIRCUIT ]

The compressed air flows from Air inlet into Pre-cooler for preliminary cooling, then passes through Evaporator for further cooling, the compressed air after refrigeration enters Moisture separator, the condensed water is separated and removed out via autodrain. The dried cool air is returned back to heat exchanger for gaining temperature, and then comes out the dryer through Air outlet

[ REFRIGERANT CIRCUIT ]

The refrigerant after passing through Refrigerant compressor becomes liquid form in high temperature and high pressure, this liquid form refrigerant flows through Condenser to cool down and then passes through desiccant filter for removing particulates. Refrigerant after passing through Capillary becomes low temperature vapour form then enters Evaporator to conduct heat exchange with incoming hot compressed air. After refrigeration process, the refrigerant returns back to Refrigerant compressor for the next cycle.

[ INSTALLATION AND MAINTENANCE ]

All KAD+ refrigerated air dryers do not require special foundation. Immediate start-up after connection of inlet and outlet pipes and power supply cable.

[ THE MAIN ADVANTAGES OF KAD + AIR DRYER ]

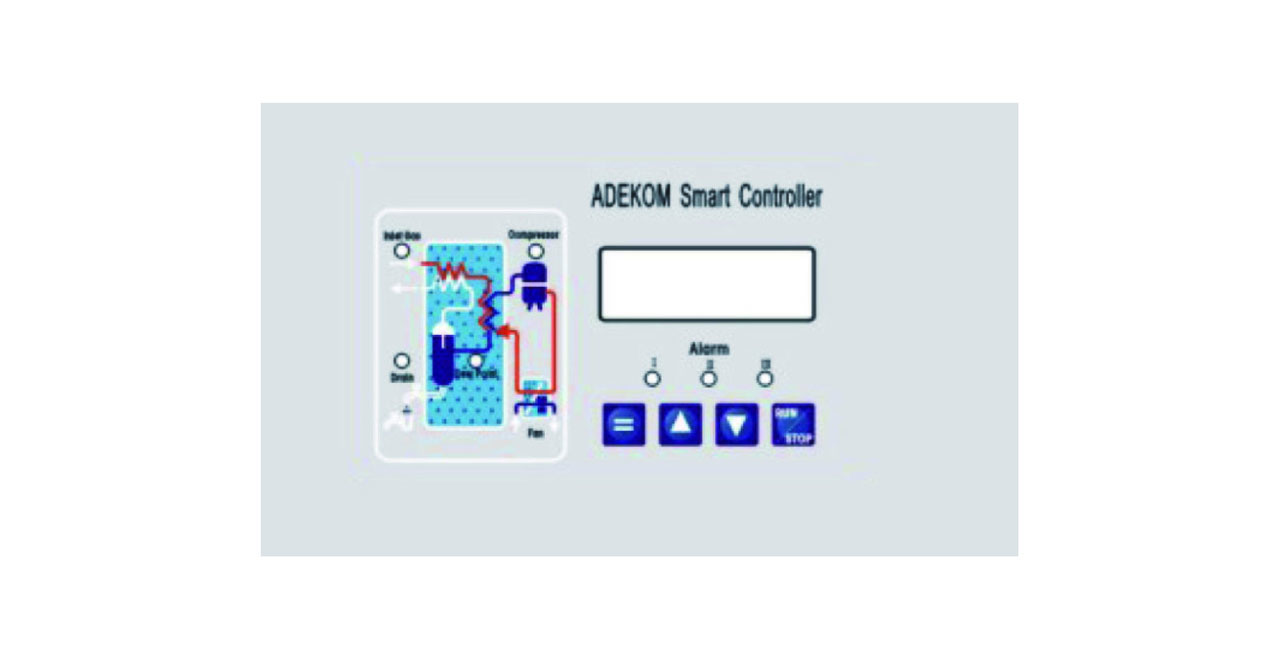

LG 5 INTELLIGENT CONTROL PANEL

LG 10 INTELLIGENT CONTROL PANEL

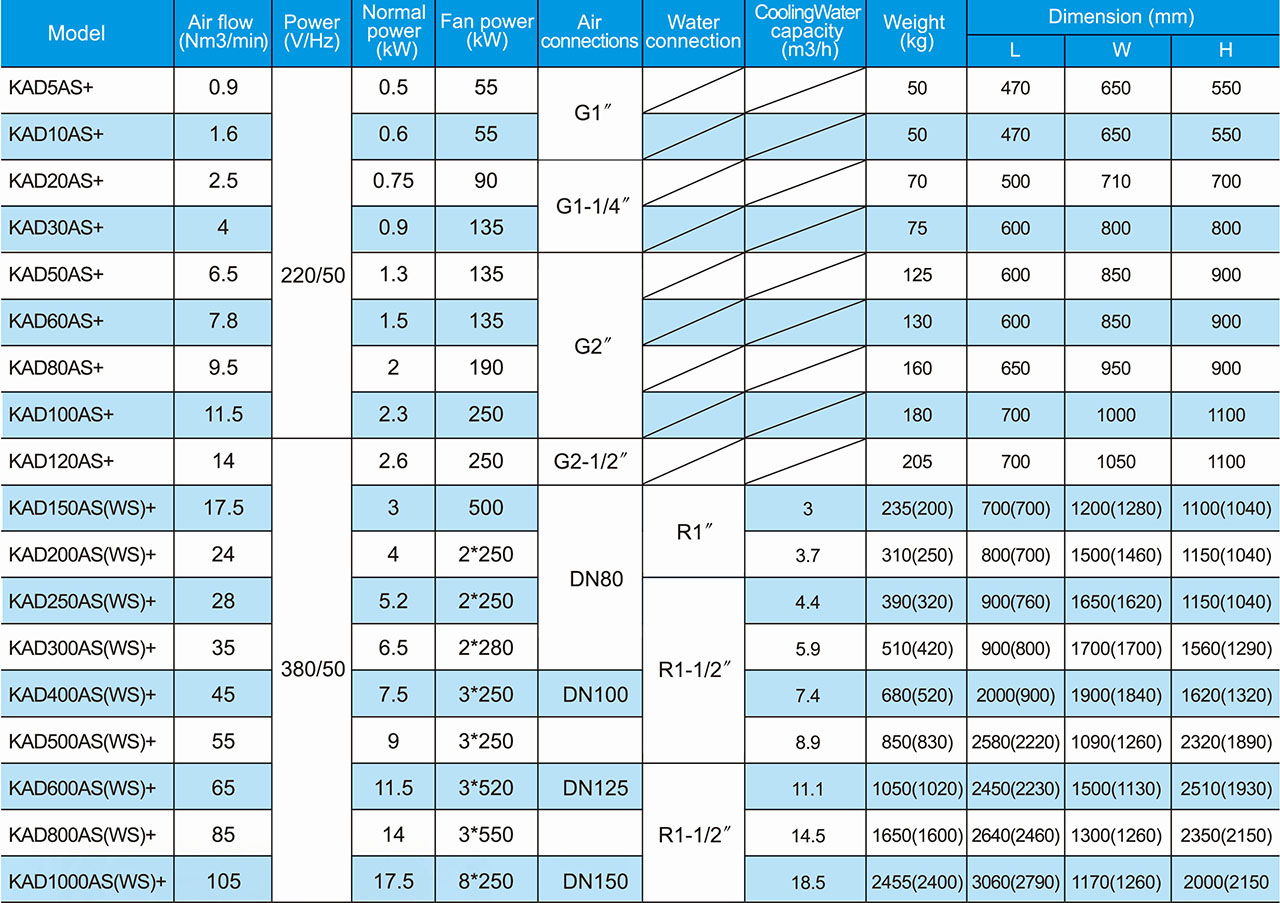

KAD + SERIES REFRIGERATED AIR DRYER

NOTE :

Standard conditions

Working conditions

Inlet air temperature correction formula

Standard temperature x Standard air flow rate = Actual air flow rate. Actual Temperature e.g. Standard air flow rate for KAD20AS+ is 2.5m3/min. If the actual inlet air temperature is 65 oC, then the actual air rate will be: x 2.5m3/min = 1.73m3/min

Working pressure correction formula

Actual air inlet pressure x Standard air flow rate = Actual air flow rate e.g. Standard air flow rate for KAD60AS+ is 7.8m3/min. If the actual inlet pressure is 10bar(g), then the actual air flow will be: x 7.8m3/min = 11.14m3/min

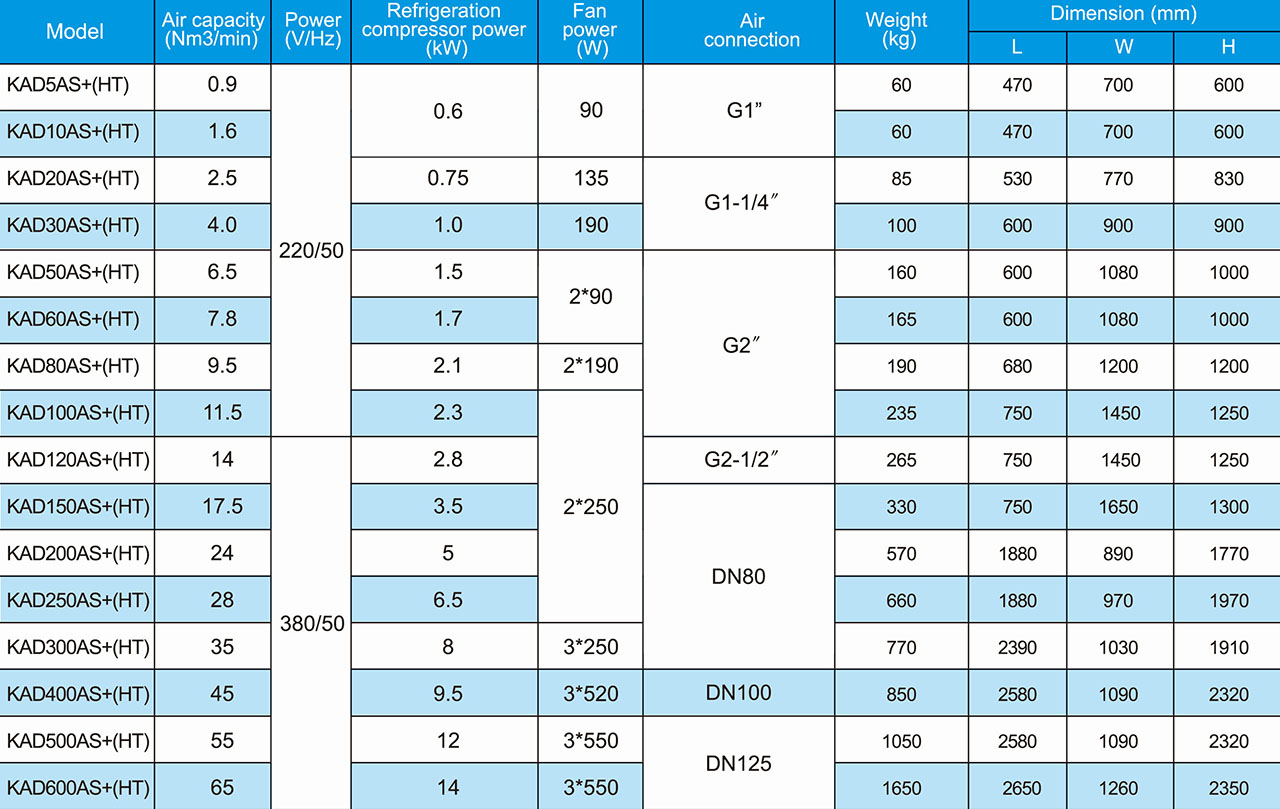

KAD + Series High Temperature Air-cooled Type Refrigerated Air Dryer

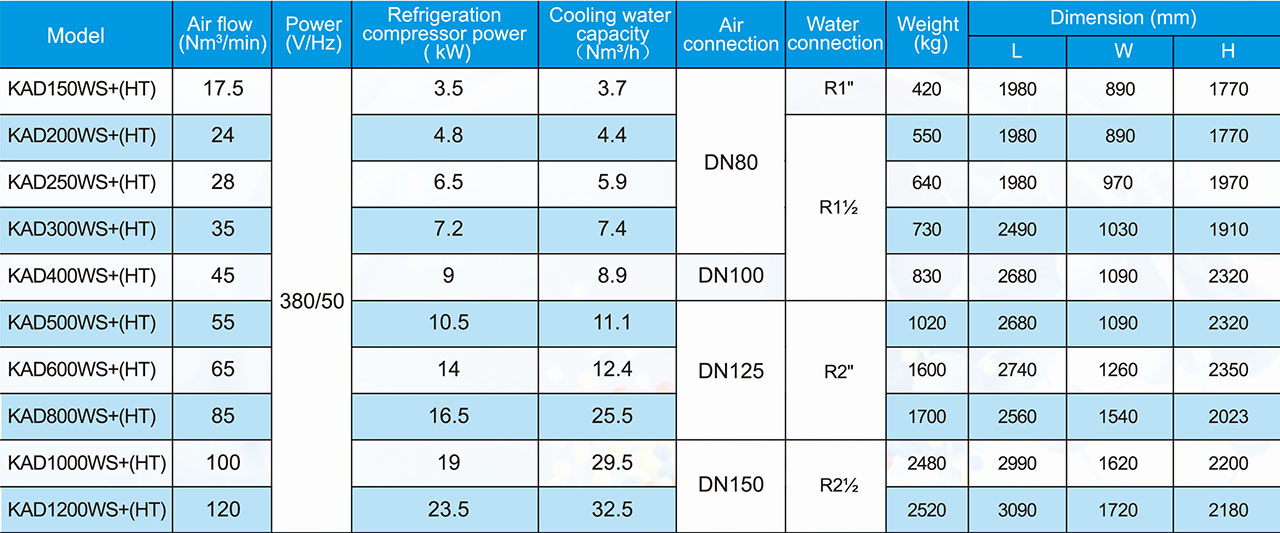

KAD + Series High Temperature Water-cooled Type Refrigerated Air Dryer

Rated operating condition :

** The configurations just for reference. Data Changes, without notice