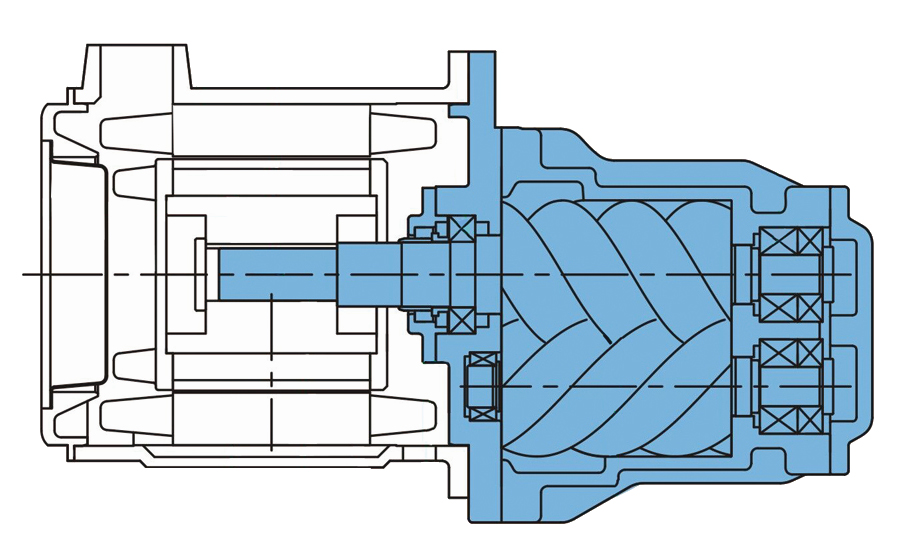

One Common Shaft Structure

- Interior permanent magnet air compressor saves USD20,000(IPM) motor is designed to be direct-couple connected with compressor airend male rotor internally with one common shaft structure to guarantee 100% transmission efficiency without any loss.

- No gears, belts or couplings that cause transmission loss.

- No motor bearings that subject to fail.

- Robust airend rotors with optimal efficiency, low vibration, low rotation speed and low noise level.

High Efficiency Oil-cooled Permanent Magnet Motor

- IPM motor constructed with neodymium iron boron permanent magnet materials can prevent demagnetized even under high operating temperature up to 180℃. Services life is up to 15 years!

- Halo-resistance enameled cable with remarkable insulation performance is applied to stator coil for long service life.

- One common shaft structure design, motor without bearing structure to guarantee 100% transmission efficiency.

- No more greasing and replacement of bearings at regular interval.

- High temperature protection via PTC/PT100 is available.

- Wide adjustable speed range and high precision which lead to wider range of air capacity modulation.

- Compact size motor saves compressor foot print.

- Double layer housing with oil circulation that reduces noise level and realizes low vibration and stable operation.

- Very high efficiency: IE4 and IP65 protection class as options.

Permanent Magnet Motor Duty Frequency Inverter

- DC reactor is equipped to suppress harmonics and improve the power factor of the input grid.

- Peak current during start-up is minimized to achieve soft starting stably.

- Saving the cost of power supply equipment.

- Special ventilation design to avoid the risk of high temperature tripping during hot climate.

- Filtration mat is fitted as standard with surface coating treatment on circuit board to realize dust and dirt resistance and anti-moisture effect.

- Follow CAN standard protocol and strictly comply with cable specification for hardware, good anti-noise interference capability.

- Fast-tracking on pressure changes, pressure fluctuation is controlled within ± 0.01Mpa, to match precisely with the system air demand by outputting the optimal frequency/speed.

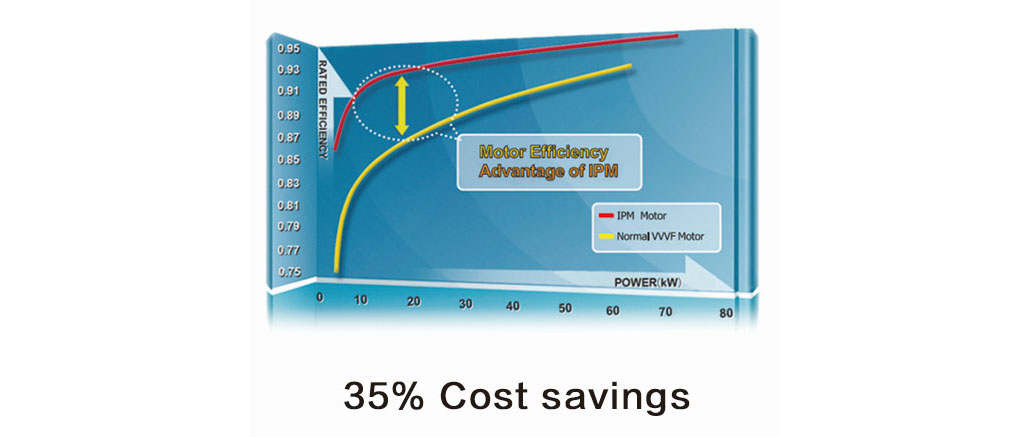

Oil-cooled permanent magnet air compressor saves USD20,000 /year in electricity cost compared to standard baseload compressor

The application of oil-cooled permanent magnet motor on 75kW VSD compressor, efficiency on average is increased by 7%, saving electricity costs USD 3,850 / year Equipped with high efficiency oil-cooled permanent magnet motor, compared with standard VSD motor, energy saving performance is more outstanding. The 75kW full load efficiency is 96.5%; while, the equivalent standard VSD motor efficiency is only 92.8%, and this alone can save 3.7%. When the speed is lower, the efficiency of the permanent magnet motor is 96.2%; while, the efficiency of the standard VSD motor is 89.6%, the average energy saving can be 7%. 75kW refers to the shaft power, actual input power is 84kW, based on 6000 hours per year, the loading rate of 70%, electricity saving: 6000H * 70% * 84kW * 7% = 24,696 kWH / year, that is, saving 24,696 * USD 0.155 = USD 3,850.

The application of inverter controlled technology - 38kW no-load energy consumption is saved, saving electricity costs USD 11,000 / year!

For a 75kW air compressor, the loading rate of 70%, which means 30% of time is running at no load, and 38kW of energy consumption is wasted. With 6000 hours of annual operation, 1800 hours is wasted with 38kW. 75kW refers to the shaft power, actual input power is 84kW, based on 6000 hours per -year, annual power consumption in full load state is 504,000kWh, but in actual operation, the no-load rate is 30%, the no-load power consumption is 38kW, which is wasted Electricity fee: 6000h * 30% * 38kW = 68400 kWh. Obviously, KD75EPM can save 68,400kWh / year, that is, saving 68,400 * USD0.155 = USD 10,600.

There is no pressure fluctuation loss-reduce pressure energy consumption and save electricity cost USD 5,500 / year!

Working pressure 8bar of standard base load compressor is actually having unload pressure of 8bar, and loading pressure 6.5bar, indicating that 6.5bar is enough for production requirement. KD75EPM can adjust the pressure to 6.5bar, thus saving USD 5,500 / year in electricity costs! Every 1 barg of system pressure reduction can save 7% of system energy consumption. 75kW refers to the shaft power, actual input power is 84kW, based on 6000 hours per year, saving electricity costs: 6000H * 70% * 84kW * 10% = 35,280 kWH / year, that is, saving electricity costs 35,280 * USD 0.155 = USD 5,500.

* No-load electricity saving is ultimately determined by the customer's site condition and air consumption

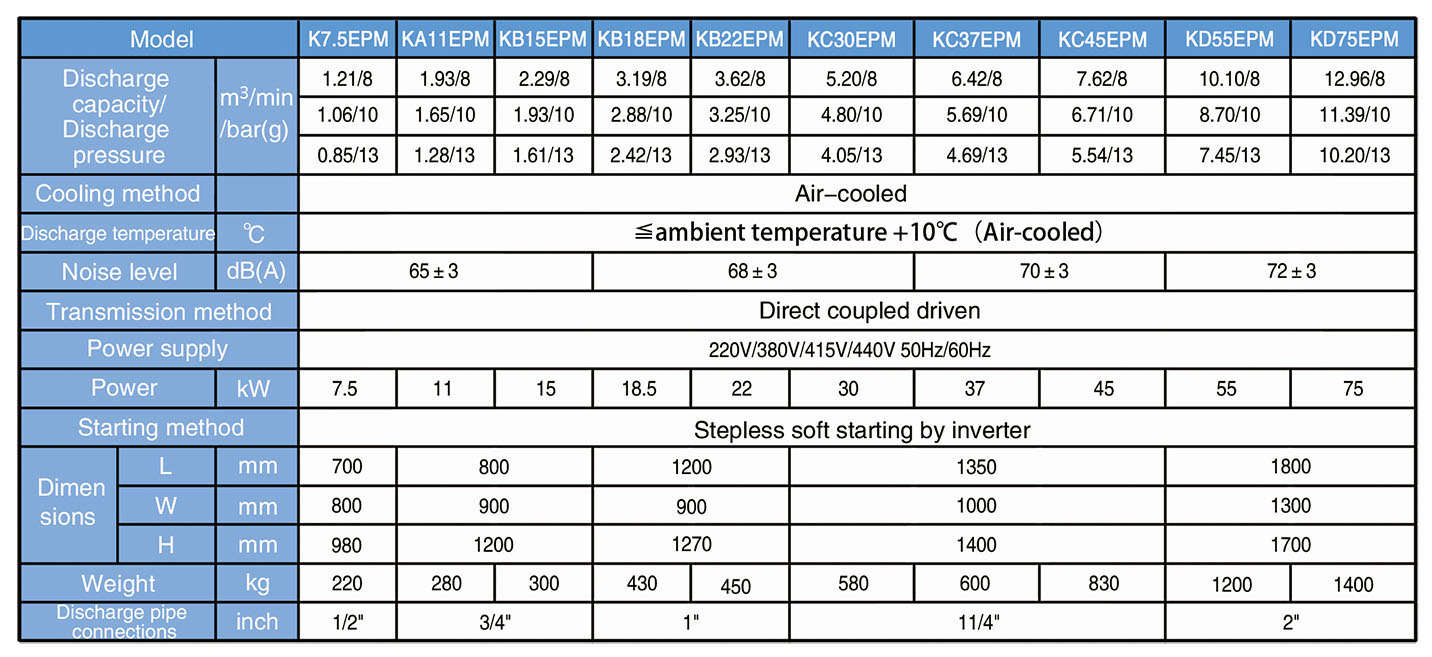

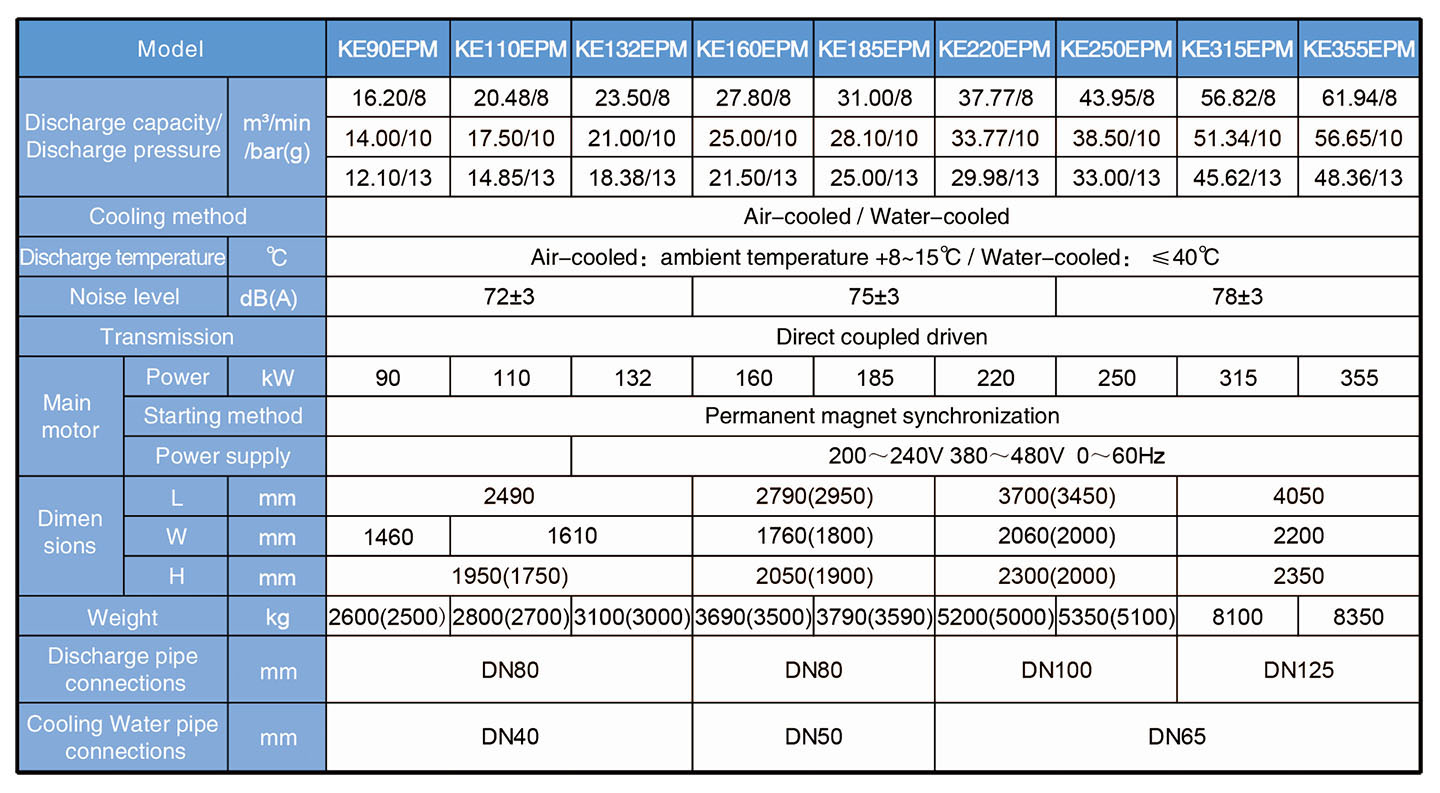

Technical Data of EPM Series Permanent Magnet VSD Screw Compressor

- Unit performance measured according to ISO 1217, Ed.3, Annex C-1996.

- Noise level measured according to Pneurop / Cagi PN8NTC 2.2 test code; tolerance ±3dB(A).

- Note: Adekom reserves the right to make changes without prior notice. For further information, please contact the manufacturer or your local sales agent.

- Note: Adekom reserves the right to make changes without prior notice. For further information, please contact the manufacturer or your local sales agent.